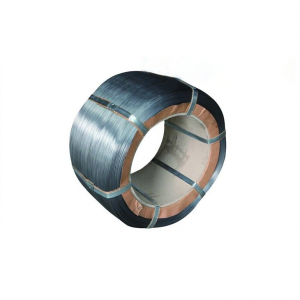

High Quality PVC/PE Glued Coated Wire For Chain Link Mesh

Plastic-coated wire is also called plastic-coated wire, PVC plastic-coated iron wire (abbreviation: PVC wire, PE wire). , anti-corrosion, anti-cracking and other characteristics, the service life is several times that of hot and cold galvanized iron wire.

The processing technology of PE glued coated wire is slightly different from that of plastic-coated iron wire. First, a mold with higher hardness must be selected. The temperature control during processing is higher than that of plastic-coated iron wire. The most important thing is to have excellent operating skills. Perfect quality plastic coated steel wire.

The thickness of the plastic wrap is relatively thick, which can reach about 200 silk, which is similar to the others, but is mostly used on “silk”.

Plastic coated wire material

, can add anti-ultraviolet, anti-aging additives.

Plastic coated wire life

High-density raw plastic, the surface water absorption rate is 0%, resistant to common acids and alkalis, and the service life is up to 12 years.

Galvanised Wire Working Specifications

Given that galvanized wire is classified according to the amount of zinc coating, the following table outlines the difference between tensile strength.

Products Description:

| Inner Dia. Range(mm) | Outer Dia. Range(mm) | Tensile (Mpa) | Elongation(%) | Zinc coating(g/m2) | Packing Size | Weight/Package |

| 2.00-4.00 | as request | 390-500 | 10 | black Annealed; Electro Galvanized; Hot Dipped Galvanized |

Coil | 1kg/coil-800kg/coil |

| 600-900 | 4 | |||||

| 1000-1400 | 4 |

Diameter Properties

Standard Galvanized Wire is manufactured to comply with the following diameter tolerances:

| Nominal Wire Diameter | Tolerance (mm) |

| over 2.00mm up to and incl. 3.00mm over 3.00mm up to and incl. 4.00mm |

+/-0.02 +/-0.03 |

Steel Chemistry

A combination of steel grades is used and heat treatment processes to manufacture soft, medium and hard tensile grades. The table below is indicative only of steel chemistries used.

| Tensile Grade | % Carbon | % Phosphorus | % Manganese | % Silicon | % Sulphur |

| Soft | 0.05~0.15 | 0.035 | 0.5 ~1.00 | 0.10~0.34 | 0.041 |

| Standard | 0.45~0.50 | 0.032 | 0.5 ~1.00 | 0.10~0.34 | 0.041 |

| High | 0.59~0.63 | 0.035 | 0.5 ~1.10 | 0.10~0.35 | 0.045 |

| Extra-High | 0.65~0.83 | 0.035 | 0.5 ~1.10 | 0.10~0.35 | 0.045 |

Quality Control:

We use total quality control system. Every pieces of the raw material; semi-finished products and finished products are tested and recorded in file. The tracking record is used from final products to the very first beginning raw material steel factories.

Third Part like SGS is available for test control before shipment

Packing:

1) All the products are packed with seaworthy packing.

2) Customer’s special requirement for packing can be satisfied.

3) Air freight; sea freight and truck freight are all available.

Application:

Widely used in animal breeding, agriculture and forestry protection, aquaculture, parks, zoos, fences, stadiums, etc., because of its anti-corrosion, anti-aging, and longer service life than ordinary iron wires.