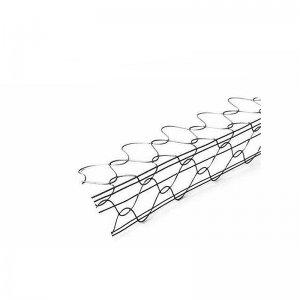

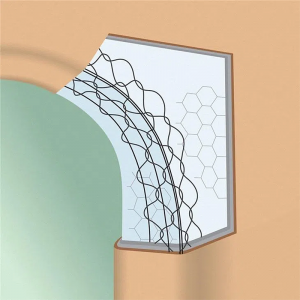

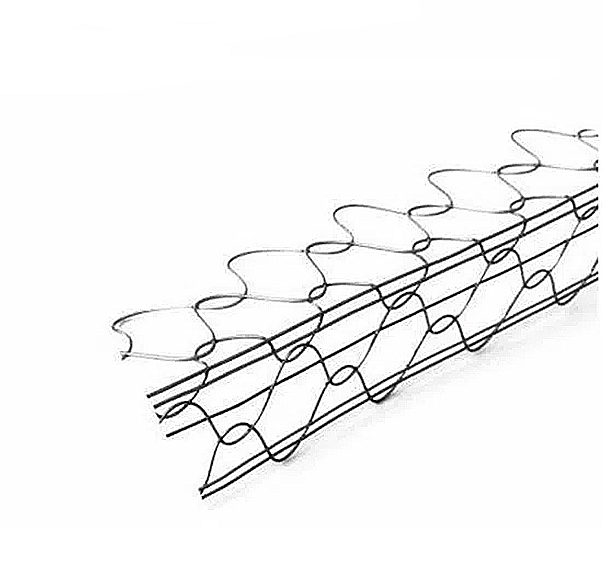

17Ga Galvanized Steel Wire For Corner Aid

Galvanized steel wire for Corner Aid is a soft,High-quality 17-gauge galvanized metal wire build for longevity.

Low carbon galvanized wire for Corner Aid & Bullnose are produced to meet the requirements of BS EN 10244; ASTM_A_641(zinc-coated) etc. The specification can be made by customer’s requirement.

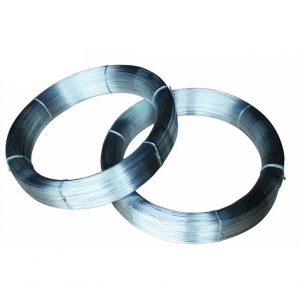

The diameter of the wire is available from 0.7874mm to 8.0mm and is available in either coils or stems.

Drawing process:

Plating before drawing process: In order to improve the performance of galvanized steel wire, the process in which the steel wire is scorched by lead, galvanized and then drawn to the finished product is called the first plating and then drawing process. The typical process flow is: steel wire – lead quenching – galvanizing – drawing – finished steel wire.

The process of drawing after middle plating: the process of drawing after middle plating is: steel wire – lead quenching – primary drawing – galvanizing – secondary drawing – finished steel wire. The characteristics of middle-plating and post-drawing are that the lead-quenched steel wire is drawn once, then galvanized, and then drawn twice to the finished product.

Mixed plating and drawing process: To produce ultra-high strength (3000 N/mm2) galvanized steel wire, a “mixed plating and drawing” process is used. The typical process flow is as follows: lead quenching—one drawing—pre-galvanizing—second drawing—final galvanizing—three drawing (dry drawing)—water tank drawing a finished steel wire. The above process can produce ultra-high-strength galvanized steel wire with a carbon content of 0.93-0.97%, a diameter of 0.26 mm, and a strength of 3921 N/mm2.

Diameter Tolerances

| Nominal Wire Diameter | Tolerance (mm) |

| over 0.80mm up to and incl. 1.60mm | +/-0.03 |

| over 1.60mm up to and incl. 2.50mm | +/-0.03 |

| over 2.50mm up to and incl. 4.00mm | +/-0.03 |

| over 4.00mm up to and incl. 5.00mm | +/-0.04 |

| over 5.00mm up to and incl. 8.00mm | +/-0.04 |

Galvanised Coating Weight – AS3863; EN 10244; ASTM A 641

| Wire Diameter(mm) | Wire Diameter (inch) | Minimum Ctg Mass Class 1 (g/m2) | Minimum Ctg Mass Class 2 (g/m2) | Minimum Ctg Mass Class 3 (g/m2) |

| 0.7874 | 0.031 | 30 | 25 | 135 |

| 0.813 | 0.032 | 30 | 45 | 165 |

| 1.24 | 0.049 | 30 | 45 | 200 |

| 2.41 | 0.095 | 90 | 245 | 365 |

| 2.68 | 0.106 | 90 | 245 | 365 |

| 2.79 | 0.11 | 90 | 245 | 365 |

| 3.68 | 0.145 | 90 | 245 | 365 |

Tensile Strength (MPa):

The tensile strength is defined as the maximum load achieved in a tensile test divided by the cross sectional area of the wire test piece. The tensile strength range is 448-517 MPa; 551-620 MPa; 65000psi~75000psi; 80000psi~90000psi

Steel Chemistry:

A combination of steel grades is used and heat treatment processes to manufacture soft, medium and hard tensile grades. The table below is indicative only of steel chemistries used.

| Tensile Grade | % Carbon | % Phosphorus | % Manganese | % Silicon | % Sulphur |

| Standard | 0.04~0.07 | 0.032 | 0.5 ~1.00 | 0.10~0.34 | 0.041 |

| High | 0.1~0.18 | 0.035 | 0.5 ~1.10 | 0.10~0.35 | 0.045 |

Quality Control:

We use total quality control system. Every pieces of the raw material; semi-finished products and finished products are tested and recorded in file. The tracking record is used from final products to the very first beginning raw material steel factories.

Third Part like SGS is available for test control before shipment

Packing:

1) All the products are packed with seaworthy packing.

2) Customer’s special requirement for packing can be satisfied.

3) Air freight; sea freight and truck freight are all available.

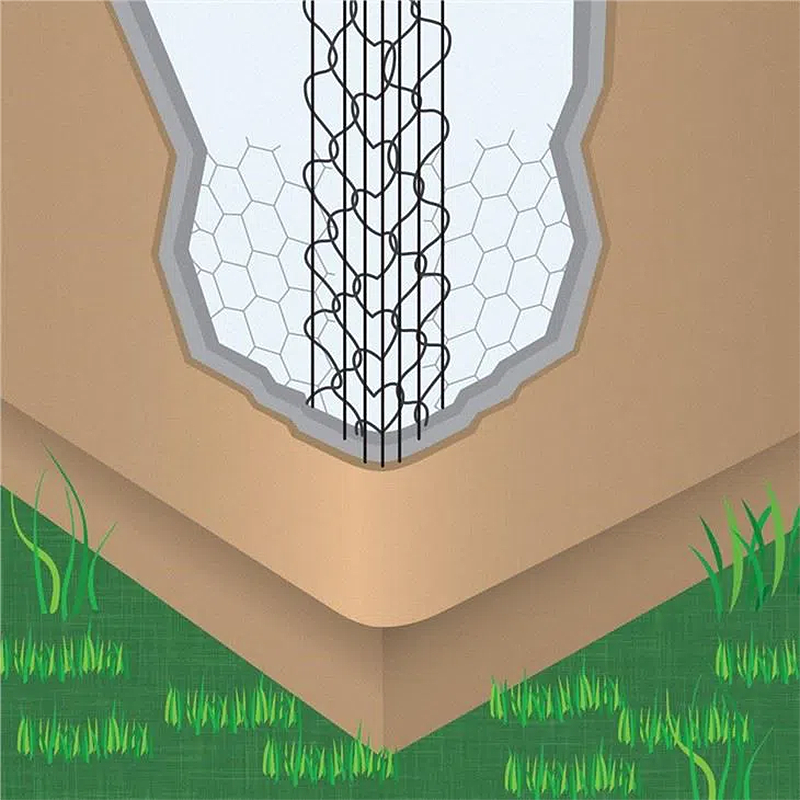

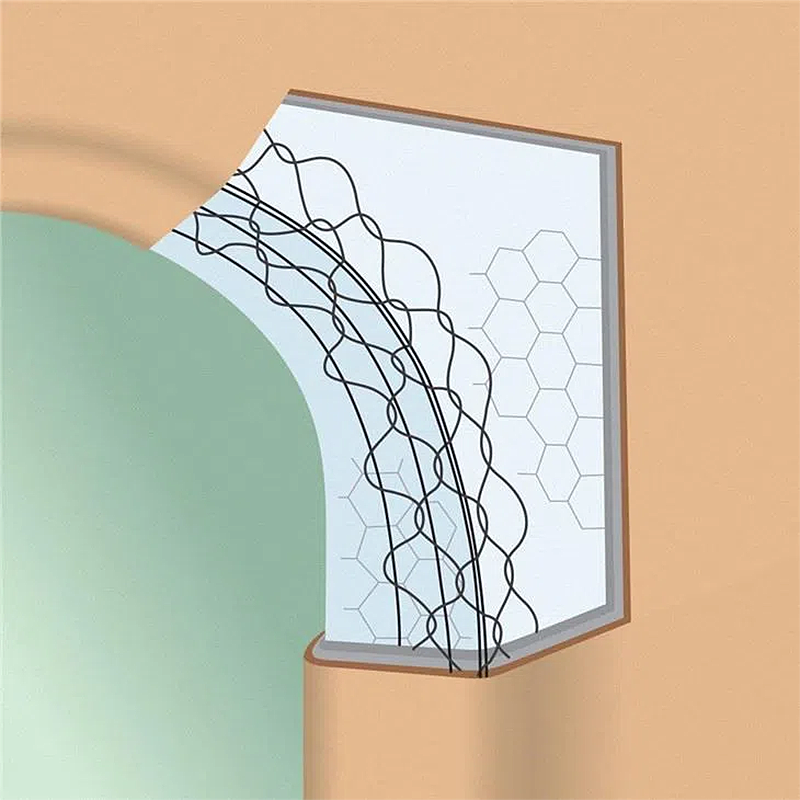

Application:

Our Company mainly specializes in importing and exporting metal material and metal products, and we also do transit trade, domestic trade and agent operation. Our products have been sold to Europe, America, New Zealand, Japan, South Korea, Southeast Asia, the Middle East, Africa and Hong Kong. We have distributors at home and abroad. “High quality, reputation and good service” is our management concept. Sincerely cooperate with friends all over the world for the mutual development.