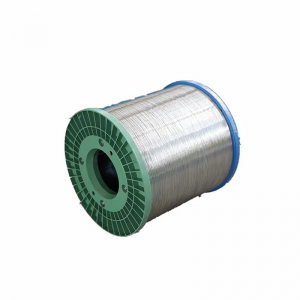

Mini Coils

Galvanized Wire is made to BS EN 10244. The metallic zinc coatings applied by the galvanizing process are an effective way of combating corrosion in steel. Galvanized wire for general manufacturing purposes is available in a standard galvanized coating or a heavy galvanized coating.

Standard galvanized coatings are smoother, however less corrosion resistant than heavy galvanized coatings and are often used in normal wire working applications. Some typical end users include cages, bucket handles, coat hangers and baskets.

Heavy galvanized coatings are used in conditions where atmospheric corrosion is severe. End users include crop support wires where chemicals are used, pool fencing or chain mesh in coastal areas.

Additional Info:

Diameter Range: Std. Gal. 0.15-8.00 mm

Diameter Range: Heavy Gal 0.90-8.00 mm

Surface Finish: Standard & Heavy Galvanized

Galvanised Wire Working Specifications

Given that galvanized wire is classified according to the amount of zinc coating, the following table outlines the difference between standard, heavy galvanized and extra-high galvanized wire.

| Nominal Diameter | Minimum Coating Mass (g/m2) | ||

| Standard Galv. | Heavy Galv. | Extra-highGalv. | |

| over 0.15mm up to and incl. 0.50mm | 15 | 30 | |

| over 0.5mm up to and incl. 0.75mm | 30 | 130 | |

| over 0.75mm up to and incl. 0.85mm | 25 | 130 | |

| over 0.85mm up to and incl. 0.95mm | 25 | 140 | |

| over 0.95mm up to and incl. 1.06mm | 25 | 150 | |

| over 1.06mm up to and incl. 1.18mm | 25 | 160 | |

| over 1.18mm up to and incl. 1.32mm | 30 | 170 | |

| over 1.32mm up to and incl. 1.55mm | 30 | 185 | |

| over 1.55mm up to and incl. 1.80mm | 35 | 200 | 480 |

| over 1.80mm up to and incl. 2.24mm | 35 | 215 | 485 |

| over 2.24mm up to and incl. 2.72mm | 40 | 230 | 490 |

| over 2.72mm up to and incl. 3.15mm | 45 | 240 | 500 |

| over 3.15mm up to and incl. 3.55mm | 50 | 250 | 520 |

| over 3.55mm up to and incl. 4.25mm | 60 | 260 | 530 |

| over 4.25mm up to and incl. 5.00mm | 70 | 275 | 550 |

| over 5.00mm up to and incl. 8.00mm | 80 | 290 | 590 |

Diameter Properties:

Standard Galvanized Wire is manufactured to comply with the following diameter tolerances:

| Nominal Wire Diameter | Tolerance (mm) |

| over 0.80mm up to and incl. 1.60mmover 1.60mm up to and incl. 2.50mmover 2.50mm up to and incl. 4.00mm

over 4.00mm up to and incl. 6.00mm over 6.00mm up to and incl. 10.00mm |

+/-0.03+/-0.03+/-0.03

+/-0.04 +/-0.04 |

Heavy Galvanized Wire is manufactured to comply with the following diameter tolerances:

| Nominal Wire Diameter | Tolerance (mm) |

| over 0.80mm up to and incl. 1.60mmover 1.60mm up to and incl. 2.50mmover 2.50mm up to and incl. 4.00mm

over 4.00mm up to and incl. 5.00mm over 5.00mm up to and incl. 6.00mm over 6.00mm up to and incl. 10.68mm |

+/-0.04+/-0.04+/-0.04

+/-0.05 +/-0.05 +/-0.05 |

Tensile Strength (Mpa):

The tensile strength is defined as the maximum load achieved in the tensile test, divided by the cross-sectional area of the wire test piece. Galvanized Wire is produced using soft, medium and hard grade wires. The following table specifies the tensile range according to the grade:

| Grade | Tensile Strength (Mpa) |

| Galvanised – Soft QualityGalvanised – Medium QualityGalvanised - Hard Quality | 380/550500/625625/850 |

Please note that the sizes mentioned above are indicative only and do not specify the size range available from my products range.

Steel Chemistry:

A combination of steel grades is used and heat treatment processes to manufacture soft, medium and hard tensile grades. The table below is indicative only of steel chemistries used.

| Tensile Grade | % Carbon | % Phosphorus | % Manganese | % Silicon | % Sulphur |

| SoftMediumHard | 0.05 max0.15-0.190.04-0.07 | 0.03 max0.03 max0.03 max | 0.05 max0.70-0.900.40-0.60 | 0.12-0.180.14-0.240.12-0.22 | 0.03 max0.03 max0.03 max |

Quality Control:

We use total quality control system. Every pieces of the raw material; semi-finished products and finished products are tested and recorded in file. The tracking record is used from final products to the very first beginning raw material steel factories.

Third Part like SGS is available for test control before shipment.

Packing:

1) All the products are packed with seaworthy packing.

2) Customer’s special requirement for packing can be satisfied.

3) Air freight; sea freight and truck freight are all available.

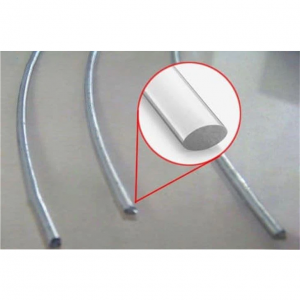

Drawing process:

Plating before drawing process: In order to improve the performance of galvanized steel wire, the process in which the steel wire is subjected to lead scorching, galvanizing and then drawing to the finished product is called the first plating and then drawing process. The typical process flow is: steel wire – lead quenching – galvanizing – drawing – finished steel wire. The process of first galvanizing and then drawing is the shortest process in the drawing method of galvanized steel wire, which can be used for drawing after hot-dip galvanizing or electro-galvanizing. Drawing after hot-dip galvanizing has better mechanical properties than drawing and plated steel wire first, and drawing after electro-galvanizing makes the zinc layer dense and resistant. Both can obtain a thin and uniform zinc layer, reduce zinc consumption and reduce the load of galvanizing line.

The process of drawing after middle plating: the process of drawing after middle plating is: steel wire – lead quenching – primary drawing – galvanizing – secondary drawing – finished steel wire. The characteristics of middle-plating and post-drawing are that the lead-quenched steel wire is drawn once, then galvanized, and then drawn twice to the finished product. The zinc layer of steel wire produced by middle plating and then pulling is thicker than first plating and then pulling. Hot-dip galvanizing can give high overall compressibility (from lead quenching to finished product), which is better than galvanizing and then drawing.

Mixed Plating and Pulling Process: In order to produce ultra-high strength (3000 N/mm2) galvanized steel wire, a “mixed plating and pulling” process is used. The typical process flow is as follows: lead quenching—one drawing—pre-galvanizing—second drawing—final galvanizing—three drawing (dry drawing)—water tank drawing a finished steel wire. The above process can produce ultra-high-strength galvanized steel wire with a carbon content of 0.93-0.97%, a diameter of 0.26 mm, and a strength of 3921 N/mm2. During drawing, the zinc layer protects and lubricates the surface of the steel wire, and no wire breakage occurs during drawing.