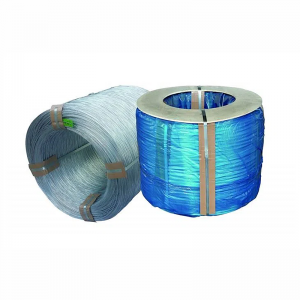

Galfan Wire For Gabion(90% Zinc + 10% AL)

Galfan steel wire has high corrosion resistance, and the corrosion resistance of its products is about 2-3 times that of ordinary pure galvanized steel wire. Whether outdoors, in wet environments, or in harsh environments such as marine climates, the corrosion resistance of this zinc alloy wire is superior to that of ordinary galvanized or electro-galvanized steel wire. The ductility and deformability of this zinc alloy wire is so high that it exceeds the steel base it protects. It can withstand winding and bending under strong deformation process conditions without fear of cracking and peeling of the zinc layer.

Galfan Wire is a new type of corrosion protection material, mainly used for thermal spraying of metal surfaces. Compared with pure zinc wire and pure aluminum wire, it has strong adhesion, good wear resistance and corrosion resistance, and superior construction performance after spraying.

| Sr.No. 1 | 2.20 mm diameter of wire - Galfan |

| 1 Tensile Strength 350-500 N/MM2 EN 10223/ EN 10244 | |

| 2 Tensile Elongation 10% Minimum EN 10223/ EN 10244 | |

| 3 Diameter of wire 2.2mm (+/-) 0.06 EN 10223/ EN 10244 | |

| 4 Zinc Coating on wire (90% Zn +10% Al) 230 GSM Minimum EN 10223/ EN 10244 | |

| 5 Zinc Adhesions on wire Zinc shall not crack during testing of wire NA (Visual Observation) EN 10223/ EN 10244 | |

| Sr.No. 2 | 2.70 mm diameter of wire - Galfan |

| 1 Tensile Strength 350-500 N/MM2 EN 10223/ EN 10244 | |

| 2 Tensile Elongation 10% Minimum EN 10223/ EN 10244 | |

| 3 Diameter of wire 2.7 (+/-) 0.06MM EN 10223/ EN 10244 | |

| 4 Zinc Coating on wire (90% Zn +10% Al) 245 GSM Minimum EN 10223/ EN 10244 | |

| 5 Zinc Adhesions on wire Zinc shall not crack during testing of wire NA (Visual Observation) EN 10223/ EN 10244 | |

| Sr.No. 3 | 3.4 mm diameter of wire - Galfan |

| 1 Tensile Strength 350 - 500 N/MM2 EN 10223/ EN 10244 | |

| 2 Tensile Elongation 10% Minimum EN 10223/ EN 10244 | |

| 3 Diameter of wire 3.4MM (+/-) 0.07 MM EN 10223/ EN 10244 | |

| 4 Zinc Coating on wire (90% Zn +10% Al) 265 GSM Minimum EN 10223/ EN 10244 | |

| 5 Zinc Adhesions on wire Zinc shall not crack during testing of wire NA (Visual Observation) EN 10223/ EN 10244 |

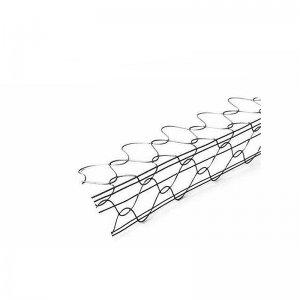

As a metal coating due to its high corrosion resistance, Galfan is mainly used in the wire mesh products industry, such as Galfan gabion mesh.