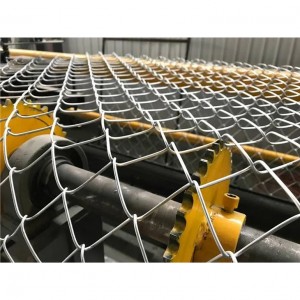

Chain Mesh Wire

Features.

1. Sturdy and stable product structure, durable and long service life.

2. Easy to use for making barbed wire.

Galvanised Chain Mesh Specifications

Galvanised Wire is made to AS/NZS 4534 “Zinc and zinc/ aluminium-alloy Coatings on Steel Wire”; BS EN 10244.

Given that galvanised wire is classified according to the amount of zinc coating, the following table outlines the difference between standard and heavy galvanised wire.

| Nominal Diameter | Minimum Coating Mass (g/m2) | |

| Standard Galv. | Heavy Galv. | |

| (W02) | (W10) | |

| Over 1.55mm up to and incl 1.80mm | 35 | 200 |

| Over 1.80mm up to and incl. 2.24mm | 35 | 215 |

| Over 2.24mm up to and incl. 2.72mm | 40 | 230 |

| Over 2.72mm up to and incl. 3.15mm | 45 | 240 |

| Over 3.15mm up to and incl. 3.55mm | 50 | 250 |

| Over 3.55mm up to and incl. 4.25mm | 60 | 260 |

Diameter Tolerances

| Nominal Diameter | Standard Galv. | Heavy Galv |

| Tolerance | ||

| over 1.00mm up to and incl. 1.60mm | +/- 0.04mm | +/- 0.05mm |

| over 1.60mm up to and incl. 2.50mm | +/- 0.06mm | +/- 0.06mm |

| over 2.50mm | +/- 0.07mm | +/- 0.08mm |

Tensile Strength (MPa)

The tensile strength is defined as the maximum load achieved in a tensile test divided by the cross sectional area of the wire test piece. The tensile strength fro all sizes of Galvanised Chain Mesh is 380 to 500 MPa.

Steel Chemistry

The table below is indicative of steel chemistries used.

| Element | % |

| Carbon | 0.05 max |

| Phosphorus | 0.03 max |

| Manganese | 0.05 max |

| Silicon | 0.12/0.18 |

| Sulphur | 0.30 max |

Product Application

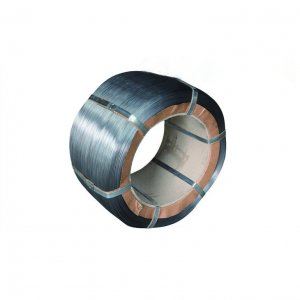

Galvanized steel wire is a carbon steel wire that is galvanized on the surface by hot plating or electroplating methods. Its properties are the same as those of straightened and tempered steel wire. Can be used as unbonded prestressing tendons, but each square meter area must be at least 200-300g zinc plating. Commonly used as parallel wire ties for cable-stayed bridges (in addition, flexible sheaths are used as outer protection).

The surface of galvanized steel wire is smooth, polished, without cracks ground, knots, prick, scars and rust, with uniform galvanized layer, strong adhesion, lasting corrosion resistance, and excellent toughness and elasticity. Tensile strength should be between 900Mpa-2200Mpa (wire diameter Φ0.2mm-Φ4.4mm). The number of twisting (Φ0.5mm) is above 20 times, and the repeated bending should be above 13 times.

The thickness of zinc layer of hot plating is 250g/m. It greatly improves the corrosion resistance of steel wire.