Elevator Steel Wire Rope

- Supply Ability

- 6000000 Meter/Meters per Month

Detailed imformation about the quality of our products:

1.Standards.

we meet GB,YB ,ASTM, DIN,EN ,JIS, KS ,IEC standards

2.Raw materials:

42A, 62A, 72A JIS G 3506

3.Range of tensil strength:

| Size of products(mm) | Tensil strength(mpa) |

| 6-16 | 1370-1770 |

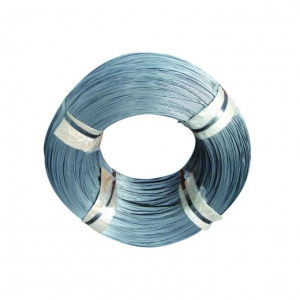

4.Packing.

| Size of products(mm) | Size of coil | Spool packing | Big coil packing(ID/OD MM) |

| 6-16 | 305/570 |

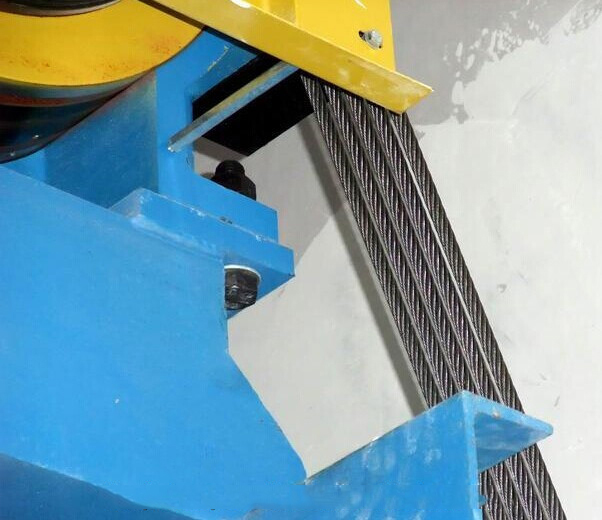

Application:

Daily maintenance:

1. Since the steel wire rope is composed of multiple steel wires (for example, the 8*19S structure steel wire rope is composed of 152 steel wires), under the working state, the relative slippage of the steel wire caused by the bending of the steel wire rope will generate a large friction force. The grease can reduce the friction between the steel wires on the premise of ensuring the friction between the steel wire rope and the traction sheave, and effectively prolong the service life of the steel wire rope.

2. The elevator wire ropes have been initially lubricated by a special spraying process, and all the wire rope surfaces are covered with a lubricating layer. If the wire rope surface is cleaned after installation, the wire rope must be post-lubricated in time.

3. The surface of the wire rope should be cleaned and maintained regularly (such as half a year or 100,000 times of operation, depending on the environment and frequency of use), and liquids such as cleaning agents should not be used to clean the wire rope during cleaning and maintenance, otherwise it will affect the rope. The oil content and oil content in the core will affect the normal use of the wire rope.

4. When cleaning and maintaining the wire rope, the surface of the wire rope should be cleaned with brush, cotton yarn, compressed air, etc. After the wire rope is cleaned, the surface of the wire rope should be oiled in time with the special grease for the wire rope.

5. Excessive lubrication will not guarantee the friction between the wire rope and the traction sheave. The grease on the surface of the wire rope should be thin and uniform (the amount of coating varies according to the grease requirements of each company).

Remember: steel wire ropes for elevators cannot be used without oil. Unlubricated wire ropes will seriously affect the life of the wire ropes and traction sheave.