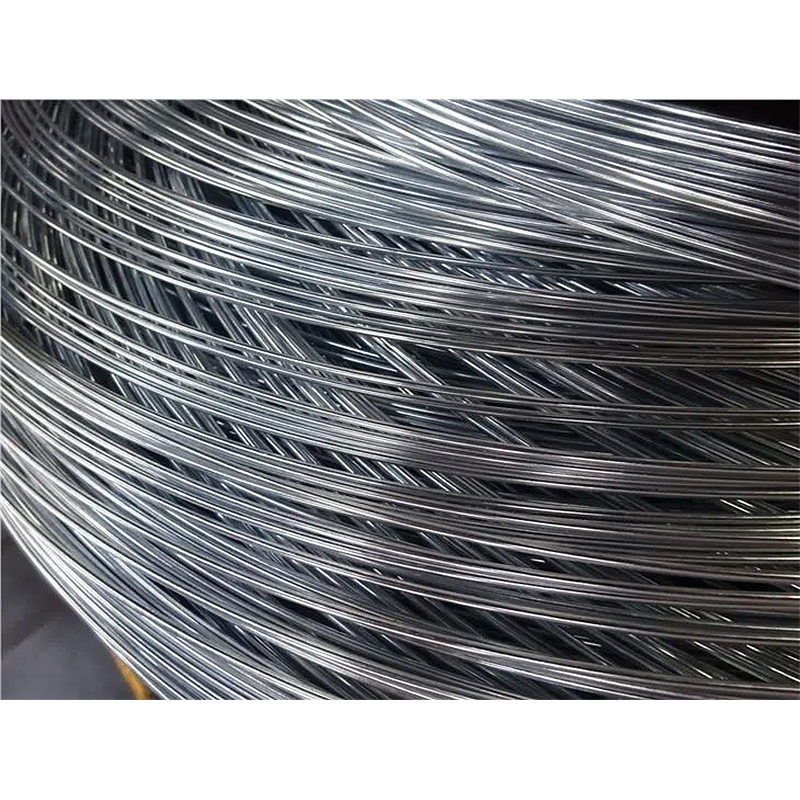

2.7mm Galvanized Wire For Chain link Fence

| Place Of Origin | Mainland China | Tensile Strength Range | 300-550Mpa 390~900Mpa |

| Brand Name | Mjh | Galvanized Layer | 30-360g/Mm² |

| Model | 0.15-3.5mm | Standard | Gb/Astm/Bs/Jis/Ksd |

| Type | Galvanized Iron Wire | Delivery Timedelivery Time | 15-30 Working Days |

| Application | Cable Armoring, Wire Mesh, Chain Link Fence, Crafts, Agriculture, Building Construction, Filter Fence Mesh, Wire Mesh For Construction, Gabion | Raw Material | Q195/Q235/1006/1008/1018 |

| Quality | Gb/T3082/Astma411 And Other Standards | Galvanized Layer | Purity 99.995% |

| Surface Treatment | Hot-Dip Galvanized | Elongation | >15% |

| Raw Material | A. Q195 Q235 Sae1006 Sae1008 Wire B. Zinc Purity 99.995% | Packing | 25~1000kg In Rolls. |

Galvanizing process is very tedious, it can be used in many places because of the excellent performance of galvanizing process and strict processing steps, good quality assurance of the safety of the user’s use, so galvanized flat wire is widely used in our life. It is processed from high quality low carbon steel coils, galvanized round wire is also divided into hot galvanized wire and cold galvanized wire (electro galvanized wire) is made of high quality low carbon steel, after drawing and forming, pickling and rust removal, high temperature annealing, hot galvanizing. It is processed through the process of drawing, pickling and rust removal, high temperature annealing, hot-dip galvanizing, and cooling. The products are widely used in various fields such as construction, handicrafts, preparation of wire mesh, making galvanized hooked wire mesh, plastering wall mesh, highway guardrail, product packaging and daily civil use.

Galvanized wire is often used in our life, it is made of high quality low carbon steel coils, after pickling and rust removal, drawing, high temperature annealing, hot galvanizing and other processes, galvanized wire has good toughness and flexibility, because of the galvanizing process, so the corrosion resistance is stronger, is widely used in construction, handicrafts, woven wire, highway fence, etc. It is widely used in construction, handicraft, woven wire, highway fence and other fields. Galvanized wire is divided into hot galvanized wire and cold galvanized wire according to the production process. Hot galvanized wire is produced by dipping in a heated and melted zinc solution, which is faster, but the thickness of galvanization varies and consumes more zinc metal. The corrosion resistance is better because the base metal forms an infiltrating layer that can last for decades in outdoor use environments.

The galvanizing process is to gradually coat the metal exterior with zinc through the unidirectional nature of the current in the electroplating bath. The production speed is faster, the galvanized layer is uniform, and the appearance is bright, but the corrosion resistance is excellent, and rusting does not generally occur for several years. Because the amount of galvanization is different between hot and cold galvanizing, it can be distinguished directly by its appearance. The color of cold galvanizing is bright, silvery white with yellow, while the color of hot galvanizing is bright and white.