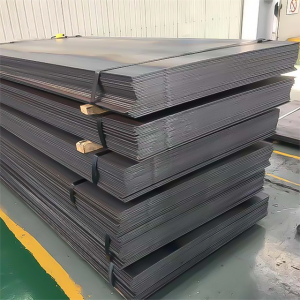

Black Iron Wire

| Product name | Black iron wire | Brand | MJH |

| Features | good elasticity and flexibility | Uses | Construction building materials, construction sites, agricultural bundling, product processing, wire mesh processing, bracket welding, nail production, deep processing products, etc. |

| Cross-sectional shape | Round | Specification | Customized |

Black iron wire has good elasticity and flexibility, and its hardness and softness can be controlled during the annealing process. It is made of high quality iron wire and is mainly used in the construction industry for binding wire and tying wire.

Process: The hot metal billet is rolled into a 6.5mm thick steel bar or coil, which is then put into a wire drawing device and drawn into different diameters of wire, and gradually reduce the diameter of the wire drawing disc, cooling, annealing, coating and other processing processes to make a variety of different specifications of wire. It contains the following components: iron, cobalt, nickel, copper, carbon, zinc, and other elements.

Black iron wire features

The main wire number is 5#-38# (wire warp 0.17-4.5mm)

Characteristics: Softer and more flexible than ordinary black iron wire, with uniform softness and color consistency.

Use: Mainly used in construction, mining, chemical industry, welding net, welding hanger, reprocessing, etc. After annealing, the wire becomes softer and more flexible, and the effect of doing construction tying wire and tying rebar is more.

Packaging: black iron wire packaging with galvanized wire packaging, the same, divided into plastic outside the linen, plastic outside the woven, and first with a thin layer of plastic will be wrapped around the wire, and then wrapped with a linen bag or woven bag will be wrapped!

1, Cold-drawn wire is a kind of metal cold processing. The raw material is coiled bar, which is often referred to as rebar, after shelling and a series of processes to produce the product, is our common wire.

2, Cold-drawn wire in the building materials used more, cold-drawn wire testing standards are different. Cold-drawn wire has high strength, and can be used in many areas, and is used more often for prestressing tendons. Not require plasticity, only the strength of the occasion, you can use such steel.

3, The process of cold-drawn wire is not complicated, cold-drawn wire manufacturers are more, good quality cold-drawn wire is very complicated, the price of cold-drawn wire is divided into different levels according to the quality of cold-drawn wire, cold-drawn wire production is also a variety of different procedures.